Contact us and

the most suitable for your projects

find crane solutions.

+90 (332) 342 54 38

Single Girder Gantry Crane

Liftkon Single Girder Gantry Crane offers an economical and efficient solution for the transportation of loads with medium load capacities in industrial facilities. Attracting attention with its compact and lightweight design, these cranes provide high performance and reliability even in tight spaces.

Superior Performance and Durability

Liftkon Single Girder Gantry Cranes offer high efficiency in handling medium tonnage loads. Manufactured in accordance with DIN Norms and FEM standards, these cranes are equipped with advanced production technologies and engineering solutions. Its long-lasting and durable structure allows it to be used safely in various industrial applications.

- Load Capacity: It can lift loads ranging from 1 ton to 50 tons.

- Areas of Use: Stockyards, marble works, machinery manufacturing, industrial storage and assembly lines.

- Building Material: It is manufactured using high quality steel and composite materials, resulting in a lightweight and durable solution.

- Overhead Cranes Overhead Travelling Cranes Overhead Crane Gantry Crane Gantry Crane

- Gantry Crane Overhead Crane Overhead Crane Gantry Crane

Technical Specifications

- Single Beam Design: The single-beam construction, compact and lightweight design makes it easy to use even in tight spaces. It offers high maneuverability and flexibility.

- Modular System: Crane components are modular, which simplifies maintenance and repair operations and reduces costs.

- Safety Features: It is equipped with advanced safety systems, ensuring the highest level of operator and environmental safety.

- Control Systems: Equipped with modern control panels and remote control systems, it offers easy and safe use with user-friendly interfaces.

Advantages

- Economic Solution: An ideal, economical and efficient solution for medium load capacities.

- Resilience High quality materials and superior engineering for long-lasting use.

- Flexibility: It can be used in different sectors and working conditions.

- Easy Maintenance: Low maintenance costs due to modular design and quality components.

Why Liftkon Single Girder Gantry Cranes?

Liftkon, with its industry experience and engineering expertise, manufactures single girder gantry cranes to meet the most demanding industrial requirements. Thanks to our customer-oriented approach and continuous R&D, we offer the latest technologies and the highest quality standards.

Make your operations more efficient, safe and economical with Liftkon Single Girder Gantry Cranes. Contact us for more information and find the most suitable crane solutions for your projects.

What is a Single Girder Gantry Crane?

Gantry craneis an important industrial equipment used for the transportation and lifting of large volumes and heavy loads. It is generally preferred in open areas or large spaces such as large warehouses and factories. Gantry cranes carry loads from one point to another thanks to a bridge structure located above the ground. This bridge moves on legs, allowing loads to be transported over a large area. It is widely used in many sectors in different industries, from production facilities to ports.

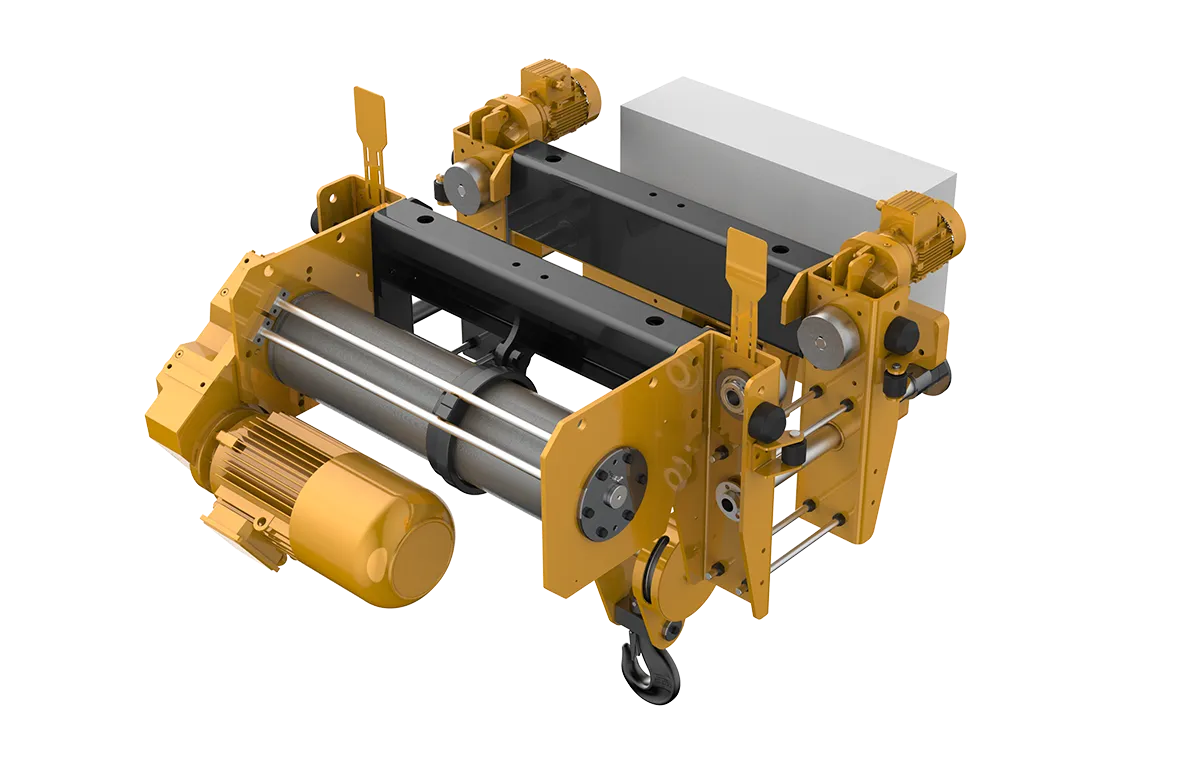

Working Principle of Single Girder Gantry Cranes

Gantry cranes basically consist of a lifting mechanism and a bridge structure that supports this mechanism. This bridge, which stands on two main columns, ensures that the loads are transported in a healthy and balanced manner. The lifting unit moves on the bridge with the crane trolley and can be precisely controlled during the transportation process. Crane operators can manage the cranes manually or with remote control systems.

Gantry cranes are especially preferred when large and heavy loads need to be transported. These cranes play an important role in transporting loads to the right point by providing flexibility in large areas.

Areas of Use

Single Girder Gantry cranes have a wide range of applications. Here are the most frequently used areas:

- Ports and warehouses: Ideal for container transportation and fast handling of large volumes of cargo.

- Factories: Used for the transportation of large machines, raw materials and products in production lines.

- Heavy industry: Used for the transportation and assembly of large parts in industries such as steel, automotive, shipbuilding.

- Construction sector: Widely used in construction projects, transportation of building materials and equipment.

Single Girder Gantry Crane Manufacturing

Gantry crane manufacturing is a process that requires high engineering knowledge and experience. Careful planning is required during the design and production phases in order to make customized production according to the needs of each enterprise. Different solutions can be offered in line with the materials used in this process, technological innovations and customer demands.

1. Design Process

The manufacturing process of Single Girder Gantry cranes starts with a detailed design phase. The crane is designed by taking into account the amount of load that the enterprise needs to lift, the width of the working area, the frequency of load transportation and environmental conditions. For example, the needs of a crane used for a factory and a crane used for a port area may be different. Therefore, engineers work to determine the most suitable system in terms of both operational and safety.

- Load capacity: Since gantry cranes are designed to lift loads that often weigh tons, determining the correct load capacity is of paramount importance.

- Working height: The height of the gantry cranes is designed according to the ceiling height in the storage or production area of the enterprise and the height distance it needs to carry.

- Bridge width: Bridge width is an important factor that determines the areas in which the cranes will move. Therefore, cranes should be designed with optimum width according to the area of operation.

2. Materials Used in Production

In order for Single Girder Gantry Cranes to be durable and long-lasting, high quality materials are used in the manufacturing process. Generally, steel materials are preferred in the structural components of these cranes. Because steel provides high strength and durability. In addition, the electrical and mechanical components of the crane systems are also subjected to the highest level of quality control.

- Steel structures: The legs, bridge and lifting system of cranes are generally made of durable steel suitable for heavy industry.

- Hoisting motors and systems: High-power motors and cables are used to transport loads safely.

- Electrical systems: Electrical systems are also of great importance for the control, safety and precision of cranes. Cranes supported by automation systems minimize the risk of operator error.

3. Special Production Gantry Cranes

Each business may have unique needs. For this reason special production gantry crane options have been in great demand in recent years. Unlike standard crane models, custom-made cranes can be fully customized for specific projects or business conditions.

For example, cranes for businesses operating in extremely hot or cold environments need to be designed to withstand these conditions. In addition, in industries where cranes come into contact with heavy chemicals or corrosive substances, production can be carried out using protective coatings and special materials. In this way, the performance of the cranes is improved while at the same time the operational efficiency of the business is maintained.

Other factors taken into account in custom-made gantry cranes are:

- Customized size and capacity: In addition to the standard dimensions, wider bridges or higher lifting capacities can be requested.

- Long distance transportation: In ports or large storage areas, wider bridges and long rail systems can be used to allow cranes to move over very large areas.

- Automation and remote control systems: Automated cranes that do not require operator intervention or systems controlled by remote control can be developed.

Single Girder Gantry Crane Prices

Single Girder Gantry crane prices may vary depending on many factors. Since the needs of each business are different, costs are also shaped according to the project. For this reason, it is important for businesses planning to purchase cranes to consider the factors affecting their budgets and make an investment accordingly.

1. Load Capacity and Dimensions

One of the most determining factors of Single Girder Gantry crane prices is the carrying capacity and size of the crane. Cranes that can lift heavier loads have more engine power, bridge width and the amount of material used, so the cost increases. For example, there can be a big price difference between a crane with a capacity of 5 tons and a crane with a capacity of 50 tons.

- Small capacity cranes: 5 to 10 tons capacity gantry cranes are generally preferred in smaller businesses or in warehouse applications. These cranes offer more economical solutions.

- Large capacity cranes: Cranes of 50 tons and above are used in larger projects such as heavy industry and large ports. These types of cranes require more complex engineering solutions, so their prices can be quite high.

2. Special Production and Customization Options

As we mentioned earlier, the prices of custom-made gantry cranes for businesses can be higher than standard models. The cost increases because custom-made cranes are equipped with materials resistant to specific industrial conditions or are produced in special sizes.

- Automation systems: Prices may vary according to the automation level of the cranes. A fully automated crane may cost more than a manual operator controlled crane. However, such systems provide a return on investment to businesses by saving labor costs in the long run.

- Remote control and safety features: Features such as extra safety equipment and remote control systems are other factors that drive up prices. Especially in businesses that operate in dangerous or difficult conditions, such features can be vital.

3. Installation and Assembly Costs

In addition to the production costs of Single Girder Gantry cranes, the installation and assembly process should also be included in the prices. In order for the cranes to operate safely, they must be installed by professional teams. In this process, factors such as the installation area of the crane, working height and ground condition can affect the installation costs. Cranes installed in large factories or open areas may require larger equipment and longer installation times.

- Standard installations: Installation costs can be more reasonable in small and medium-sized projects. Crane installation is easier, especially in areas with flat floors such as warehouse applications.

- Challenging field conditions: Installation can be more complex in large ports, construction sites or areas exposed to extreme weather conditions. In such projects, crane installation times are longer and costs increase.

4. Maintenance and Spare Parts Costs

The cost of Single Girder Gantry cranes is not only limited to the purchasing phase. In the long run, operating costs should also be taken into consideration. Regular maintenance of cranes and spare parts requirements can be a significant cost item for businesses. Although quality cranes are long-lasting, parts that wear out over time need to be replaced and regular checks should be carried out.

- Warranty period: The maintenance of the cranes during the warranty period is usually covered by the manufacturer. However, after the warranty period expires, maintenance and repair costs remain to the enterprise.

- Spare parts supply: Spare parts can be costly, especially for special production cranes. In standard models, spare parts may be more easily available and more affordable. Therefore, when purchasing a crane, the spare parts procurement process and costs should also be taken into consideration.

5. Operating and Utilization Costs

The operation of Single Girder Gantry cranes involves energy consumption and labor costs. Especially large capacity cranes can be costly in terms of energy consumption. However, modern cranes are equipped with energy-efficient systems, helping businesses reduce energy costs in the long run.

- Energy consumption: High power cranes consume more energy. However, with the right operating procedures and efficient motor systems, these costs can be minimized.

- Operator training: Operators need to be trained to use cranes safely and efficiently. These training processes can bring additional costs to businesses. However, well-trained operators ensure that cranes last longer and failures are prevented.

Gantry Cranes: Design, Applications, and Benefits - Crane & Hoist

Gantry Cranes and Traveling Groups

After Sales Support and Warranty

For Single Girder Gantry cranes, the purchasing process is followed by after sales support and Guarantee services are of great importance for businesses. These services play a critical role in the efficient and long-lasting use of the crane. A good after-sales support service ensures business continuity and helps to resolve potential malfunctions quickly.

1. Warranty Period and Scope

The warranty period of Single Girder Gantry cranes may vary according to the manufacturer. Generally, quality manufacturers offer long warranty periods for their cranes. The warranty covers all mechanical and electrical malfunctions related to the functionality of the crane. During this period, if any problems occur, the manufacturer provides free repair and spare parts supply.

- Comprehensive warranty: An all-component warranty guarantees all parts and functions of the crane. This gives businesses more confidence and allows for trouble-free operation of the cranes.

- Limited warranty: Some manufacturers only warrant certain parts or for a limited period of time. In this case, businesses may face extra costs if the warranty period expires or if an out-of-scope failure occurs.

2. Spare Parts Supply

In order to ensure trouble-free operation of Single Girder Gantry Cranes for many years spare parts supply is of great importance. The parts used in gantry cranes may wear out over time and need to be replaced. A good manufacturer offers its customers a fast and cost-effective supply of spare parts. In addition, the authenticity of the spare parts is critical to maintain the performance and safety of the crane.

- Fast spare parts supply: In order to ensure the production continuity of businesses, it is vital that spare parts are supplied quickly. Delays in the supply of spare parts can disrupt business processes and cause costly production downtime.

- Original parts: Genuine spare parts increase the performance of the cranes and prevent possible breakdowns. If non-genuine parts are used, the life of the cranes may be shortened and frequent breakdowns may occur.

3. Maintenance and Repair Services

Regular maintenance of Single Girder Gantry Cranes ensures their long service life. By performing periodic maintenance and repairs of cranes, manufacturers prevent possible major malfunctions. In addition, regular maintenance is also important for the cranes to remain within the scope of the warranty.

- Periodic maintenance: Periodic maintenance of cranes ensures that they maintain their performance and operate smoothly for many years. Periodic maintenance should not be neglected, especially in cranes used in harsh conditions such as heavy industry and ports.

- Emergency repair services: Unexpected breakdowns can cause major disruptions in businesses. For this reason, it is of great importance for business continuity that crane manufacturers offer emergency repair services. With a quick intervention, cranes can be brought back into operation in a short time, minimizing production losses.

4. Training and Technical Support

In order to use Single Girder Gantry Cranes correctly, operators and maintenance teams must be given the necessary training. Manufacturers provide after-sales technical support and training services to ensure the most efficient use of the crane.

- Operator training: Trainings on proper use and safety precautions ensure efficient use of the crane and prevent work accidents. In addition, training of operators contributes to fewer breakdowns and long life of cranes.

- Technical support: When cranes have any problems, it is a great advantage to quickly reach the technical support line and get guidance to solve the problem. A good manufacturer offers continuous technical support to its customers.

As a resultWhen purchasing single girder gantry cranes, not only price but also after-sales support and warranty services should be considered. These supports ensure that the cranes are used efficiently for many years and offer great advantages to businesses.

SIMILAR PRODUCTS