Contact us and

the most suitable for your projects

find crane solutions.

+90 (332) 342 54 38

Double Girder Bridge Overhead Cranes, Overhead Crane, Overhead Crane

Liftkon Overhead Crane, Double Girder Overhead Cranes, Overhead Crane - High Capacity and Performance

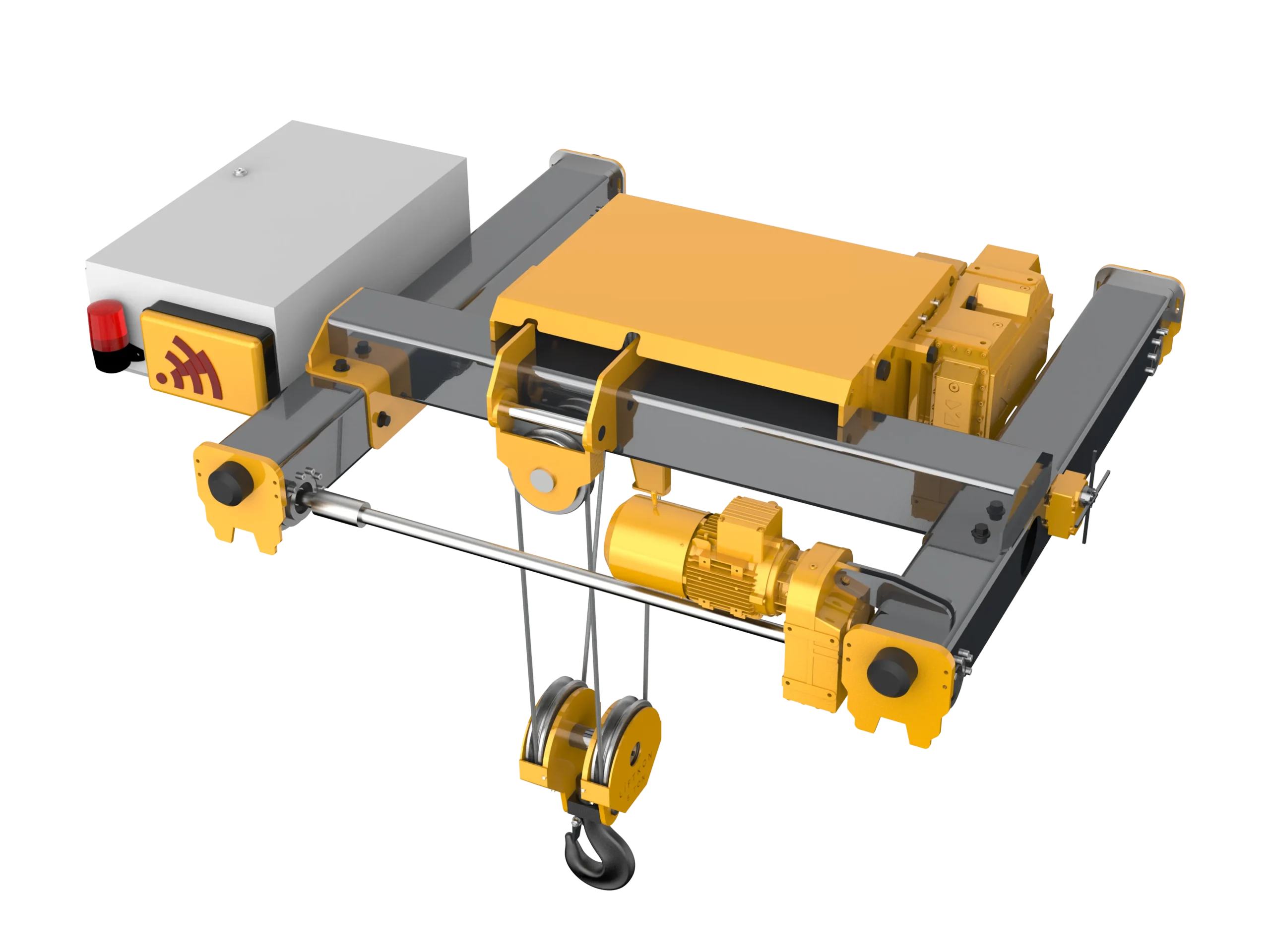

Liftkon Overhead Crane, Double Girder Bridge Overhead Cranes, Overhead Crane we manufacture. It offers unlimited capacity and high performance in industrial load lifting operations. These cranes, which can be produced in the desired capacity, offer ideal solutions especially in buildings with high ceilings and wide axle spacing. Thanks to their double girder structure, they provide higher lifting capacity and altitude compared to single girder cranes.

Technical Excellence and Safety

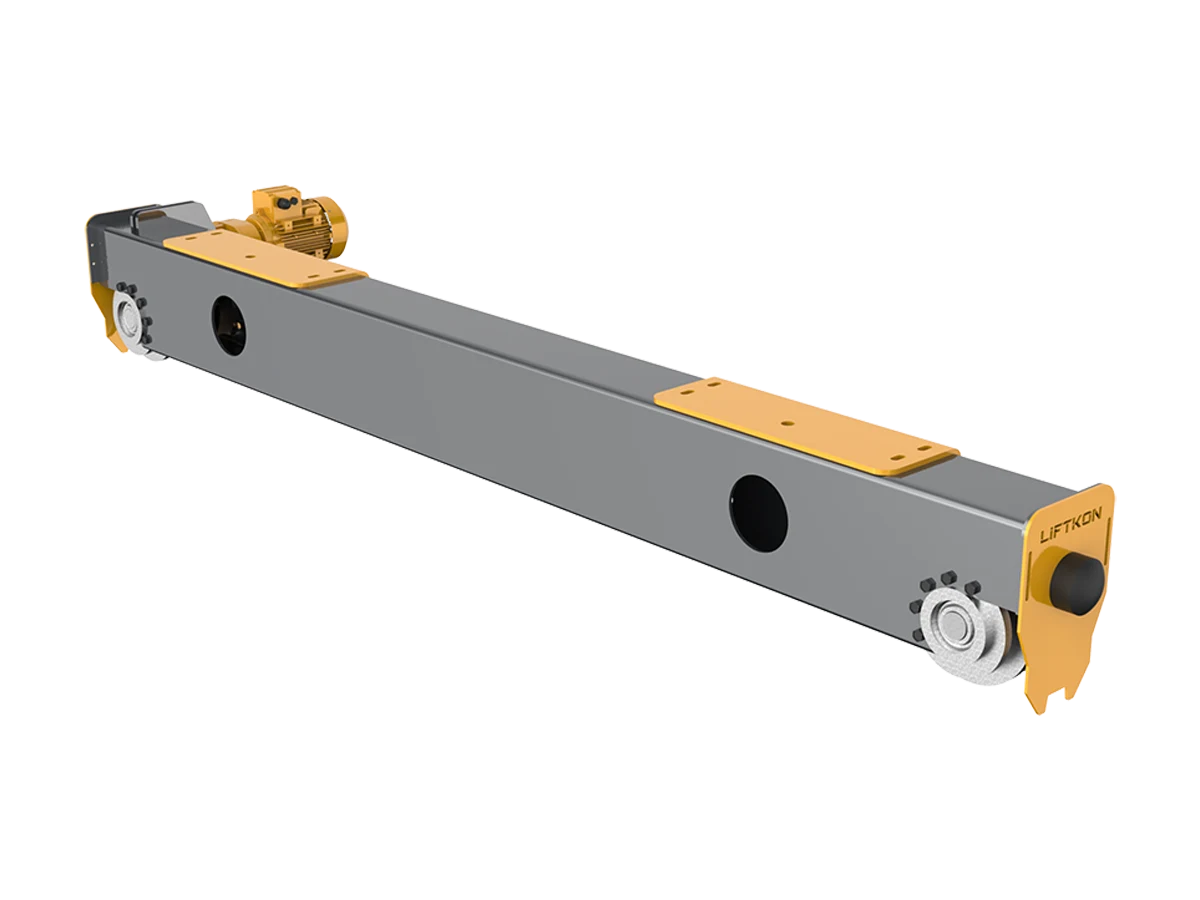

Liftkon Overhead Cranes, Double Girder Overhead Cranes Overhead Crane is manufactured in the lightest and most robust structure with optimized bridge girders in accordance with DIN and FEM standards. Four corner solid material or type A rail is used on the bridge as crane rails. There is a full-length maintenance platform on at least one girder for crane maintenance, repair and service. Energy supply and cable transportation systems are placed between the girders, providing an aesthetic and safe working environment.

- Load Capacity: Possibility of production in desired capacity.

- Beam Type: The double girder structure provides high lifting capacity and altitude.

- Areas of Use: Industrial plants with high ceilings and wide axle spacing, machinery manufacturing, iron and steel industry, power plants, mines, ports.

- Rail Type: Four corner solid material or type A rail.

- Safety Features: Advanced safety systems, overload sensors and load indicator.

- Overhead Crane, Double girder bridge Overhead Cranes, Overhead Crane

- Overhead Crane, Double girder bridge Overhead Cranes, Overhead Crane

Advanced Technology and Ease of Use

Liftkon Double Girder Overhead Cranes, Overhead Crane and Overhead Travelling Crane are equipped with user-friendly control systems and modern technology. It offers flexible and safe use with remote control and cable control options. Operator comfort and safety are ensured with fixed or movable crane control cabin. Crane walking heads protect structural safety by transmitting minimum load to the walkways and building.

- Control Systems: Remote control and wired control options.

- Crane Control Cabinet: Fixed or movable control cabinet options.

- Walking Heads: Minimum structural load transmission.

- Energy Supply: Power supply and cable transportation system between the beams.

Information from Wikipedia about Double Girder Bridge Cranes from here you can reach.

Why Overhead Crane, Double Girder Bridge Overhead Cranes, Overhead Crane?

With its industry experience and engineering expertise, Liftkon manufactures double girder overhead cranes to meet the most demanding industrial requirements. Thanks to our customer-oriented approach and continuous R&D, we offer the latest technologies and the highest quality standards.

Make your operations more efficient, safe and economical with Liftkon Double Girder Overhead Cranes. Contact us for more information and find the best double girder overhead crane solutions for your projects.

- Double girder gantry overhead cranes There is no limit in capacity. We have production in desired capacity.

- Double girder overhead cranes It is generally used in buildings that do not have altitude problems and have a large axis spacing.

- Bridge girders According to DIN and FEM standards, they are optimized to be the lightest and most robust for the relevant class of operation.

- Single girder overhead cranes provides more lifting height.

- Crane rail as a four-corner solid material on the bridge or Type A rail is being used.

- Overhead crane maintenance, repair and at least one beam has a full-length maintenance platform for its service.

- Crane energy supply and the cable transportation system is usually placed between the beams to prevent visual pollution.

- Crane traveling gear to the ceiling with an I profile as it usually works by pressing the rail from the top overhead crane It can be done.

- Remote control cranes, one more line of cable carrying profile is laid on the platform side for cable control. In addition, fixed or movable crane control cabinet can also be used.

- Load indicator desired cranes overload used for loadcellThe information received from the data is transferred to a screen to meet the need.

- Crane traveling heads by its very nature crane walkwaysand transmits a minimum load to the building.

Double Girder Bridge Overhead Cranes Overhead Crane, Overhead Crane: Industrial Load Handling Solutions

Safe and efficient transportation of heavy loads in the industrial sector is of great importance in terms of increasing the efficiency of business processes. Overhead cranes and overhead crane systems are one of the most preferred equipment to perform these operations in heavy industrial facilities such as factories, warehouses and ports. These cranes play a critical role in various business processes and help production lines run smoothly.

In this article, we will discuss in detail what overhead crane and overhead crane systems are, in which areas they are used and the advantages they provide for businesses. We will also discuss how important it is for businesses to choose the right crane.

Overhead Cranes with Bridge, Overhead Crane, What is an Overhead Crane?

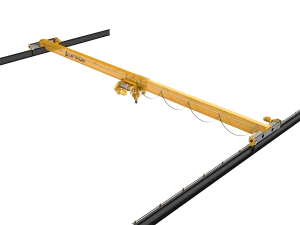

Double Girder Gantry Overhead Cranes are crane systems that are mounted on ceiling structures and can move horizontally and vertically. These cranes enable the transportation of heavy loads from one point to another and are often used in large areas such as factories, workshops, production facilities and warehouses. Overhead cranes can be of different types in terms of lifting capacity, crane hook mobility and control mechanisms.

Main advantages of Double Girder Bridge Overhead Cranes, Overhead Crane, Overhead Crane:

High Lifting Capacity: It can comfortably lift and carry loads weighing tons.

Productivity: Control by a single operator reduces labor costs and increases the speed of operation.

Safety Provides a safer working environment compared to manual handling methods.

Precision Handling: Allows precise placement of loads at the desired points.

Differences Between Double Girder Bridge Overhead Cranes, , Overhead Crane, Overhead Crane

Although both types of cranes are used for heavy load handling, they differ according to their areas of use and the advantages they provide.

Double Girder Bridge Overhead Cranes, Overhead Crane, Overhead Crane are generally preferred in narrower and closed areas, while overhead cranes are used in wider and open areas.

Since it is mounted on the ceiling structure, it does not take up space on the floor and provides more efficient use of factory space. On the other hand, Double Girder Overhead Cranes need large areas as they move on the floor.

Double Girder Overhead Cranes are more efficient for horizontal transportation over longer distances, while overhead cranes are more effective for vertical lifting.

Double Girder Bridge Overhead Cranes, Overhead Crane, Overhead Crane Why Choosing the Right Crane as an Overhead Crane is Important?

Choosing the right type of crane for a business can greatly affect business processes. Choosing the wrong crane can lead to inefficient operation of production lines, occupational accidents and high maintenance costs. Therefore, it is very important for businesses to choose the right crane for their needs.

Double Girder Overhead Cranes, Overhead Crane, Overhead Crane, Overhead Crane Some factors to consider when choosing a crane:

Weight of the load to be lifted: Each type of crane has different lifting capacities, so the weight of the loads is an important criterion when choosing a crane.

Size of the Area: Depending on the size of the facility and the area where the crane system will be used, overhead or overhead crane should be preferred.

Operation Speed: Faster and automated systems can be preferred to increase the speed of business processes.

Safety Ensuring that cranes with high lifting capacity comply with safety standards plays a vital role in preventing occupational accidents.

If you are looking for an efficient and safe load handling solution in your company, it is of great importance to choose the most suitable crane system for your business needs. Crane manufacturers such as Liftkon Crane provide great convenience to businesses in industrial load handling operations by offering solutions suitable for all kinds of needs.

What to Consider When Choosing Overhead Cranes?

Industrial load handling solutions play an important role in today's business world. Factories, workshops, warehouses and other industrial facilities often rely on crane systems. These crane types offer great advantages in terms of increasing the speed of load handling processes and ensuring occupational safety. However, choosing the right crane system is critical to ensure efficiency and safety that meets the needs of businesses. We will discuss in detail the important points you should consider when choosing an overhead crane.

1. Load Weight and Lifting Capacity

One of the most important factors when choosing Double Girder Overhead Cranes is the weight of the load to be lifted. The lifting capacities of the overhead crane vary according to the crane model. Choosing a crane with an appropriate capacity according to the weight of the load increases both safety and operational efficiency. For example, using a crane designed for loads of 5 tons would be a wiser choice than choosing a crane that carries less load.

2. Workspace

The size and characteristics of the area where the Double Girder Overhead Cranes will be used is a determining factor in the selection. craneWhile it is generally preferred in closed spaces, narrow and high places as it is mounted on ceiling structures, crane is used in larger and open areas as it moves on the ground. Therefore, the size and shape of the working area is important in determining which crane system is more suitable.

3. Mobility

The mobility of Double Girder Gantry Overhead Cranes is an important factor affecting the handling time and accuracy of loads. Overhead cranes can generally move horizontally and vertically, while overhead cranes only move horizontally. Depending on the needs of your business, you should evaluate which mobility is more suitable for handling loads. If loads will be moved frequently in different directions, a more flexible system is preferable. Mobility has a direct impact on operational efficiency. Faster and safer transportation of loads allows business processes to run more efficiently.

4. Safety Standards

It is critical that Double Girder Overhead Cranes comply with safety standards to prevent occupational accidents. You should make sure that overhead cranes are designed in accordance with specific safety standards and regulations. In addition, periodic maintenance of the cranes is another important factor that will increase the level of safety. Safety systems used in cranes are essential to ensure operator and environmental safety. Also, whether the cranes have passed safety tests will determine whether your business complies with safety standards.

5. Energy Source

The energy source required for the operation of Double Girder Overhead Cranes is also an important selection criterion. There are cranes that work with electric, hydraulic or pneumatic systems. Electric overhead cranes are generally more widely used, while hydraulic systems are preferred for heavy loads. Choosing a crane suitable for the energy infrastructure of your business will reduce energy costs in the long run. In addition, energy-saving crane systems also support environmental sustainability. The energy consumption rates of cranes can have an impact on the overall energy efficiency of the business.

6. Maintenance and Support

Double Girder Overhead Cranes need regular maintenance. You should investigate how well the crane system you choose offers maintenance and support services. Solid technical support for long-term use will increase the efficiency of your business. The warranty and maintenance contracts offered by the crane manufacturer are also an important factor. Maintaining cranes not only improves safety, but also extends their lifespan.

7. Cost and Return on Investment

Finally, you should consider the cost factor when choosing Double Girder Overhead Cranes, Overhead Crane. While choosing an affordable crane may save money initially, it may result in high maintenance costs or poor performance in the long run. Therefore, you should consider the total cost of the crane system and the return on investment it will provide to your business. Cost analysis of crane systems helps you make a choice that is in line with the budget of the business. In addition, the increased productivity and time savings provided by cranes can offset costs in the long run.

8. Application Area

The areas where Double Girder Overhead Cranes, Overhead Crane will be used is another important factor to consider when choosing a crane. In many sectors such as construction, manufacturing, logistics and storage, these crane systems are used in different application areas. For example, overhead cranes are preferred for transporting large loads in the construction industry, while overhead cranes may be more effective in storage areas. The application areas of cranes are a factor to be considered in the selection process. Choosing the appropriate crane system ensures that work processes are accelerated and safety is increased.

9. User Training

The use of crane systems requires specific training and expertise. You should check whether appropriate training is provided for the operators of the crane system you choose. Operators must be knowledgeable in order to use cranes safely and effectively. User training improves occupational safety and ensures that cranes are used efficiently. In addition, operators' knowledge of the characteristics and control mechanisms of cranes plays an important role in preventing accidents.

10. Manufacturer and Brand Assurance

Finally, the manufacturer and brand assurance of Double Girder Overhead Cranes, Overhead Crane is another important factor to consider in the selection process. A reliable and well-known brand is more advantageous in offering crane systems that comply with quality and safety standards. The warranty, maintenance services and technical support offered by the manufacturer ensure the longevity of the cranes. In addition, research on the manufacturer can help you learn about the performance and reliability of the crane system. A good manufacturer prioritizes customer satisfaction and offers quick solutions when needed.

Conclusion

They are indispensable parts of load handling operations in the industrial field. The factors to be considered in choosing the right crane are the main factors that will increase the efficiency and safety of businesses. Choosing the right crane system by considering criteria such as load weight, working area, mobility, safety standards, energy source, maintenance and cost will play a critical role in the success of your business.

For more information about crane systems and to find the right solution for your needs, it is recommended that you contact an expert manufacturer. Liftkon Craneprovides safe and efficient solutions for your load transportation processes by offering the most suitable crane systems for your business needs. Choosing the right crane is not only

Double Girder Overhead Cranes, Overhead Crane and Overhead Travelling Crane: Warranty and Spare Parts Support

Having an important place among industrial load handling solutions, they play a major role in increasing the productivity of enterprises. However, warranty and spare parts support are critical for the long-lasting and safe use of these cranes.

The safety and performance of cranes is directly related to the warranty period provided by manufacturers. A quality manufacturer sets high standards in the design and production of cranes and offers its customers a long-term warranty. This guarantee provides assurance to businesses against possible malfunctions or performance problems. A long-term warranty period reduces maintenance costs and supports business continuity. For example, in the event of a breakdown in cranes, repairs to be made under warranty make a significant contribution to the business budget.

Spare parts support is as important as the warranty. Cranes are at risk of wear and tear under intensive use. Therefore, the supply of spare parts ensures that cranes can be repaired quickly in the event of any malfunction. By offering original spare parts, a reliable manufacturer improves the performance and safety of cranes. The use of original parts ensures the longevity of the cranes and guarantees compliance with safety standards. For example, the use of original spare parts increases the lifting capacity and safety of the cranes.

In addition, during the maintenance and repair of cranes, the timely supply of appropriate spare parts allows the production process of the enterprise to continue without interruption. This is a critical factor in ensuring that business processes are not interrupted and customer satisfaction is increased.

After-sales support must take into account the warranty and spare parts support offered by the manufacturer. With the right support, businesses can increase their productivity and take important steps to ensure occupational safety.

In conclusion, when choosing an overhead crane and overhead traveling crane, warranty and spare parts support are vital to the success of your business. Working with a reliable manufacturer increases the safety of your business processes and ensures a long-term return on investment. It is essential to consider these factors to maximize the performance of the cranes and facilitate maintenance processes. Liftkon Craneprovides high quality solutions by securing your business processes with the warranty and spare parts support it offers to its customers.

SIMILAR PRODUCTS