Gantry Crane Travelling Group

The gantry crane traveling group is a critical component that ensures safe and efficient transportation of heavy loads. It offers the highest performance with durable wheels, powerful motor and brake system. The selection of the traveling group in gantry cranes is of great importance in terms of crane safety and efficiency.

Contact us and

the most suitable for your projects

find crane solutions.

+90 (332) 342 54 38

Gantry Crane Travelling Group

Strong, Reliable, On the Move

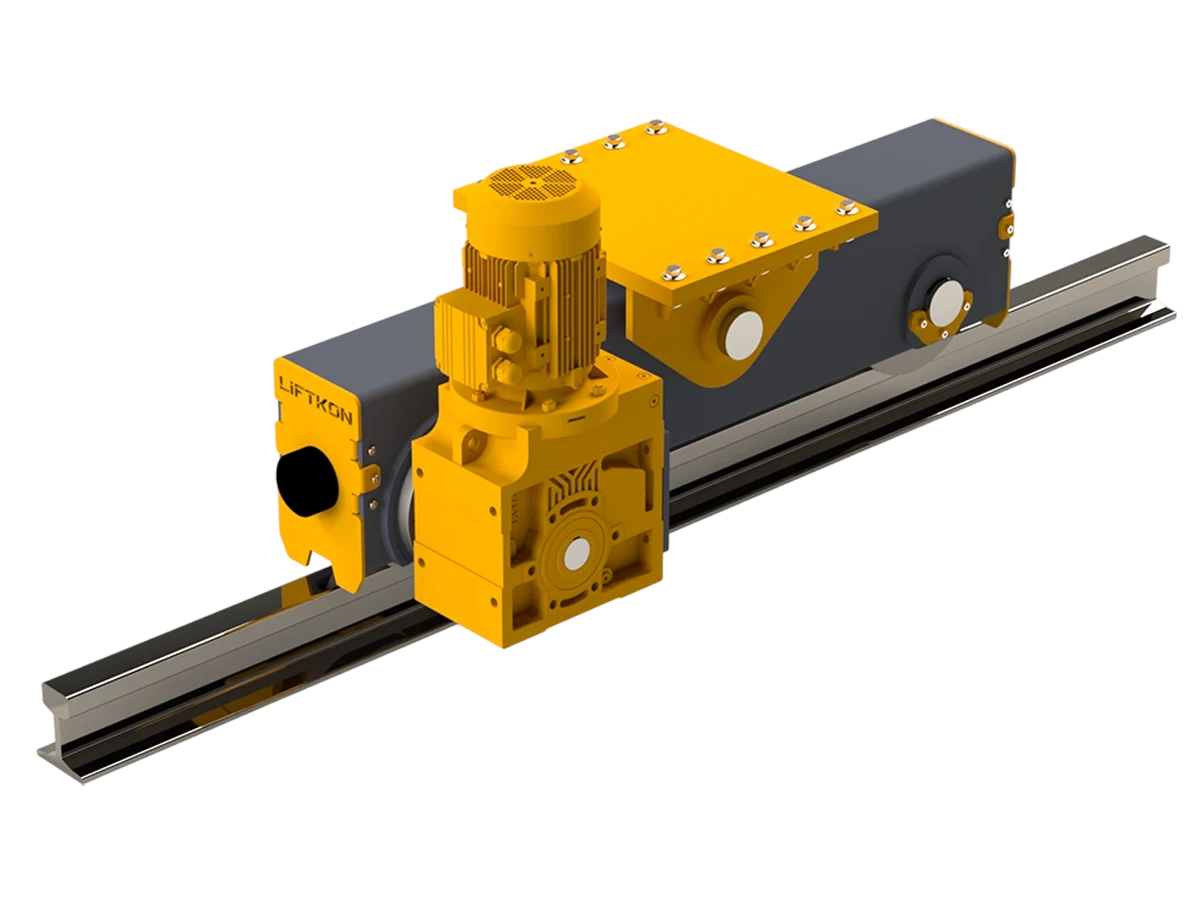

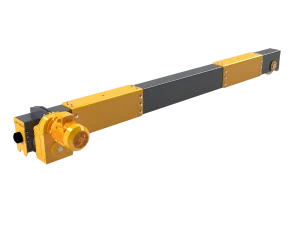

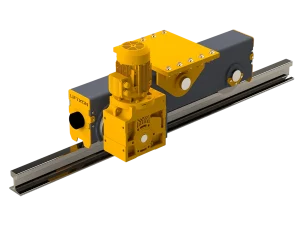

Liftkon's Gantry Crane Traveling Group is one of the key components of industrial crane systems. Manufactured with robust design and durable materials, these groups are ideal for ensuring stable movement of cranes. Each equipped with carefully selected wheel blocks and double wheel assemblies, they allow cranes to move safely and efficiently on the horizontal rail plane.

Technical Specifications:

- Wheel blocks made of high-strength steel

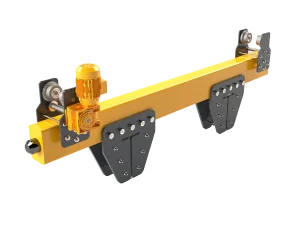

- Specially designed double wheel groups

- Complete ease of assembly and disassembly

- High performance horizontal mobility

- Excellent stability in axis and rail plane

Technology: Liftkon's engineering expertise and innovative technology set the Gantry Crane Traveling Group apart from other solutions in the industry. Meticulously engineered in every detail, these groups deliver superior performance even in the harshest industrial environments.

Why Liftkon? Liftkon offers the best solutions to its customers with years of experience and technical expertise. Our products, such as Gantry Crane Traveling Group, are known for their robust construction and long-lasting performance. Each of our products is designed and manufactured with an approach that prioritizes customer satisfaction.

Gantry crane systems are important equipment that enable the transportation of heavy loads in industrial facilities and one of the key components of these systems is gantry crane traveling groupis. While the traveling group provides the horizontal movement of the cranes, it allows a safe and effective load handling operation. In this article, detailed information about the gantry crane traveling group will be given, how this system works, which components it consists of and the points to be considered in its selection will be discussed. It will also examine the maintenance of this important part and how to prevent possible failures.

gantry crane traveling group

For the production and manufacture of gantry cranes and traveling groups here Look.

What is a Gantry Crane Traveling Group?

Gantry crane traveling groupis among the main components that enable gantry cranes to move. The traveling group moves on rails located at the bottom of the crane system. This movement allows the crane to move horizontally across the job site and move loads from one place to another. Since the traveling assembly has a direct impact on crane performance, it is vital that it is designed and selected correctly.

Walking Group Components

The gantry crane traveling group consists of various components and each component plays an important role in the smooth operation of the system:

- Wheels: The wheels used in the traveling groups allow the crane to move on the rails. These wheels are usually made of steel and must have high durability. Wear of the wheels can adversely affect the performance of the crane, so they need to be checked regularly.

- Bearing System: The bearing system, which ensures smooth rotation of the wheels, is an important part of the traveling assembly. This system reduces friction during the movement of the crane and increases energy efficiency. The bearing system should be made of quality materials for long life.

- Engine and Drive System: The motor and drive system, which allows the gantry crane traveling group to move, controls the crane movement. Motor power determines the speed and direction of the traveling group. The drive system transmits this power to the wheels, allowing the crane to move horizontally.

- Rails: The rails on which the traveling group moves allow the crane to move smoothly on the job site. The rails are usually made of steel and must have a smooth surface. Any deformations in the rails can adversely affect the movement of the crane and pose safety risks.

- Brake System: The braking system allows the crane to stop and control its movement. The brakes used in gantry cranes are usually electromagnetic brakes. This system allows the crane operator to safely move the load and stop the crane when necessary.

- Control System: The control of the traveling group is usually realized by means of a control system. With the help of this control system, the crane operator controls the movements of the crane and guides the loads correctly.

Considerations in Choosing a Gantry Crane Traveling Group

The correct selection of the gantry crane traveling group is critical for the performance and safety of the crane. Here are some important points to consider when choosing:

- Load Capacity: The amount of load to be carried by the gantry cranes is one of the most important factors determining the capacity of the traveling group. The traveling group must be designed and manufactured to withstand the weight of the loads to be carried. Otherwise, overload and malfunctions may occur in the crane system.

- Movement Speed: How fast the crane moves on the job site depends on the motor power of the traveling group and the drive system. If the crane is to carry loads quickly, the motor of the traveling group must be powerful enough to meet this speed demand.

- Working Environment: The environmental conditions in which the gantry cranes will be used play an important role in the selection of the traveling group. For example, if the cranes will be used in an open air environment, the traveling group must be resistant to external factors. Factors such as humidity, dust, extreme temperature can affect the performance of the traveling group.

- Rail Quality: A smooth surface of the rails is important for the smooth operation of the traveling group. Any deterioration in the rails may cause the crane to move in an unstable manner. For this reason, attention should be paid to rail quality and regular maintenance should be performed.

- Brake and Safety Systems: Safety should always be prioritized in gantry cranes. The reliability of the brake systems used in the traveling group is vital in terms of preventing possible accidents. At the same time, additional safety systems used for emergencies should also be included in the traveling group.

Maintenance of Gantry Crane Traveling Group

The gantry crane traveling group is a component that requires regular maintenance. In order to maintain the performance and longevity of the traveling group, the following maintenance steps should be considered:

- Wheel and Rail Controls: The wheels and rails on the traveling group must be checked regularly. Worn or deformed wheels can prevent the crane from moving properly and cause malfunctions. Similarly, deterioration of the rails also adversely affects the movement of the crane.

- Lubrication: Regular lubrication of the moving parts of the drive train reduces friction and prevents wear. Especially the wheels and the bearing system should be lubricated regularly.

- Engine and Drive System Maintenance: The motor and drive system of the traveling group are the most important components that provide the movement of the crane. Regular inspection and maintenance of these systems ensures efficient operation of the crane.

- Brake Checks: The braking system ensures that the crane stops safely. Checking the brakes regularly and replacing them when necessary is of great importance for occupational safety.

- Electrical Controls: The electrical components of the drive train provide power to the motor and drive system. Electrical cables, connections and other electrical components should be checked regularly. Loose connections or corroded cables can adversely affect the performance of the hoist.

Conclusion

Gantry crane traveling groupis one of the most critical components of crane systems and its correct selection, installation and maintenance are vital to the crane's performance and occupational safety. The traveling group facilitates the transportation of heavy loads by providing horizontal movement of the cranes. Therefore, factors such as load capacity, motor power, working environment and rail quality should be carefully considered when selecting the traveling group. At the same time, regular maintenance and controls ensure smooth operation of the traveling group and contribute to its long life. The gantry crane traveling group plays a critical role in the success of the crane system and therefore managing this component correctly provides great advantages for businesses.

SIMILAR PRODUCTS