Contact us and

the most suitable for your projects

find crane solutions.

+90 (332) 342 54 38

Click here for overhead crane design and calculation

Click for overhead crane prices

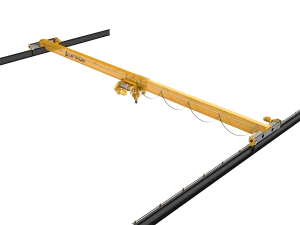

Single Girder Overhead Cranes, Overhead Crane: Innovative Solution for Industrial Transportation

Overhead cranes are an effective system used for the transportation of light and medium weight loads. This crane, which is frequently preferred in industrial areas to ensure safe and fast transportation of loads, offers many advantages. Detailed information about single girder crane, single girder overhead crane and single girder overhead crane will be given. In addition, the advantages, usage areas, technical specifications and maintenance processes of these systems will be discussed.

What is a Single Girder Overhead Crane?

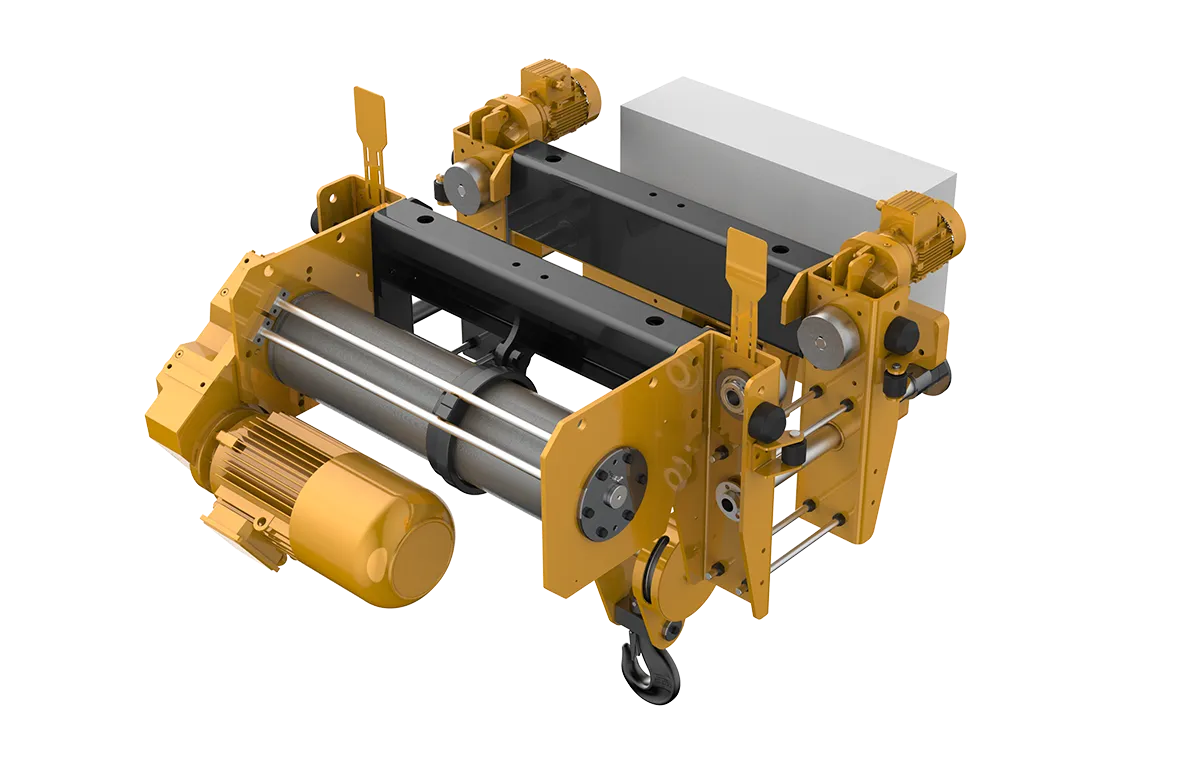

Overhead traveling cranes are a crane system that moves on a single girder. This structure makes the crane mechanism lighter and can work effectively even in tight spaces. It is often used in industrial plants, workshops, warehouse areas and construction sites. This system can be manufactured in different capacities to handle various loads.

Single Girder Bridge Bridge Crane

Single girder gantry overhead craneis a system that moves on a single beam and carries loads. These cranes are generally preferred in narrow spaces as they occupy less space. Single girder overhead crane is the version of this system suitable for ceiling installation. The main difference between the two systems is the installation location. While a single girder crane can operate at floor level, a single girder ceiling crane moves in the ceiling area.

Overhead cranes overhead crane, information from wikipedia about single girder overhead cranes from here you can reach.

Single Girder Overhead Crane

Single girder gantry overhead craneis a system designed to carry loads horizontally. This crane has a high carrying capacity thanks to its single girder structure. Overhead cranes are generally used in large areas for the transportation of heavy loads. The most important advantage of this system is that the loads can be moved easily.

Advantages of Single Beam Overhead Crane

- Space Efficiency: Single girder overhead cranes make the best use of space. They can work effectively even in tight spaces.

- Lightweight Structure: Single girder cranes have a lighter structure. In this way, they can operate with lower energy consumption.

- Easy Installation: These systems usually contain fewer components and are therefore easier to install.

- Economic Solutions: Single girder overhead cranes offer economical solutions in terms of both purchase cost and operating cost.

- Security: Single girder overhead cranes are equipped with safety measures. Systems that prevent loads from falling increase the safety of operators.

Single Girder Bridge Overhead Cranes Considerations When Choosing an Overhead Crane

When purchasing a single girder bridge overhead crane, there are some important criteria to consider:

- Load Capacity: The crane to be selected must be suitable for the weight of the loads to be carried. Crane capacity is a critical factor for work safety.

- Movement Space: The size of the area where the crane will move plays an important role in model selection.

- Intended Use: The purpose for which the crane will be used should be taken into account when selecting the model. For example, a model designed for continuous use should be selected.

- Mounting Location: The characteristics of the area where the crane will be installed (ceiling height, wall structure, etc.) must be taken into consideration.

- Ease of Maintenance: Overhead cranes are easy to maintain, reducing costs in the long term. Easily accessible components ensure fast maintenance.

Application Areas of Single Girder Bridge Overhead Cranes and Overhead Crane

- Production Facilities: Single girder overhead cranes are widely used for material handling in production facilities.

- Warehouse Areas: Ideal for handling and placing loads in warehouse areas.

- Construction Areas: It is an effective solution for transportation of heavy materials in construction projects.

- Workshops: These systems are used in workshops to transport workpieces.

- Automotive Sector: Widely used in automotive factories for the transportation of parts.

Maintenance Processes of Single Girder Overhead Cranes and Overhead Crane

Regular maintenance is important for the efficient operation of a single girder overhead crane. Maintenance processes can be categorized under the following headings:

- Periodic Controls: The crane should be checked at regular intervals. These checks help to assess the overall condition of the crane system.

- Lubrication: Regular lubrication of moving parts reduces friction and prevents wear.

- Load Tests: Testing the crane to its maximum load capacity is a critical step to ensure safety.

- Safety Equipment: Safety equipment on the crane (emergency stop, load sensors, etc.) must be checked for operation.

- Cleaning: Keeping the crane clean helps ensure its long life. Dust and dirt can reduce the efficiency of moving parts.

Safety of Single Girder Overhead Cranes and Overhead Crane

Overhead cranes single girder overhead crane are equipped with various systems to ensure safety during load handling operations. These safety measures include:

- Emergency Stop Buttons: Buttons that allow the operator to stop the crane in an emergency.

- Load Sensors: Sensors that warn if the load exceeds the capacity.

- Limit Switch: Systems that allow the crane movement to be limited to a specific area.

- Overload Protection: Protection mechanisms that are automatically activated if the crane exceeds the specified load capacity.

Conclusion

Overhead cranes have become an indispensable element of industrial transportation. They are preferred in many sectors with their lightweight structure, space efficiency, safety measures and economic solutions. These cranes provide great advantages to businesses by accelerating business processes in the areas where they are used.

Choosing the right crane, maintenance processes and safety measures are critical to increase the productivity of businesses. Single girder overhead crane, bridge overhead cranes contribute to the development of the industrial world, offering a reliable solution for load transportation.

SIMILAR PRODUCTS